Over the past couple of weeks I’ve handled a few issues with my E39 M5. I replaced the drive belts, fixed an issue with the center console and added an ABS heat shield.

DIY events through the CCA chapter are back! Long-time club supporter Craftsman Auto Care hosted us at their Fairfax location. It was the first DIY event since the pandemic shutdown. It was great to see everyone and to work with a lift again. I had noticed a belt that looked cracked so I was replacing both the AC belt and the serpentine belt that drives the alternator, power steering and water pumps.

Since I had to remove the fan to replace the belts I also bought a replacement fan. I chose not to replace the fan clutch because I knew a previous owner already had and it was operating properly. Everything went smoothly and Craftsman technician Mark was helpful in ensuring I installed the new belts properly.

I also took care of a cosmetic issue with the M5 center console. Back in 2018 I replaced the tinanium interior trim with technical graphite, a deep blue color. Over time the center console piece seemed to pop up and not lie flat. I removed the arm rest and center console to see what was going on.

It wasn’t hard to see the problem. Both of the plastic anchor points where the screws go in were broken. I could have broken something in 2018, or it might of happened when a previous owner installed the Rogue short shifter kit. Or just the natural consequence of BMW choosing to use plastic pieces.

I ended up gluing washers around the openings that thicker screws could grab onto.

Finally, a little bling for the engine bay. One fun thing about enthusiast ownership is the cottage industries that develop around the vehicles. A fellow enthusiast will come up with some kind of aftermarket improvement in their spare time. An example is Bluebus, a Bluetooth module developed by Ted, an engineer who designed it as a side hustle. The module gives older BMWs from the late 90s and early aughts all the phone and music functionality of new BMWs. It’s on my list for purchase once wait times decrease.

In the meantime, a M5 Facebook group member named Kevin Anderson has designed a shield for the E39 ABS module. This module sits exposed in the engine bay and is subjected to a lot of heat. I’ve not had any issues with the ABS module in the M5, but I did have one go bad in my 2001 530i.

Kevin designed a fiberglass shield that protects the module from the heat coming off the engine block. He offered it at a fair price to group members and I bought one. Installing was easy as it uses two existing connection points, one beneath the passenger side filter and the other on the module bracket.

So that’s what’s kept me busy on the M5 front. I enjoy these projects and have turned BMW maintenance into a hobby. But increasingly I’m also protecting my investment. The value of these cars continues to increase. No one makes normally aspirated, RWD, manual transmission sports cars any more, and they never will.

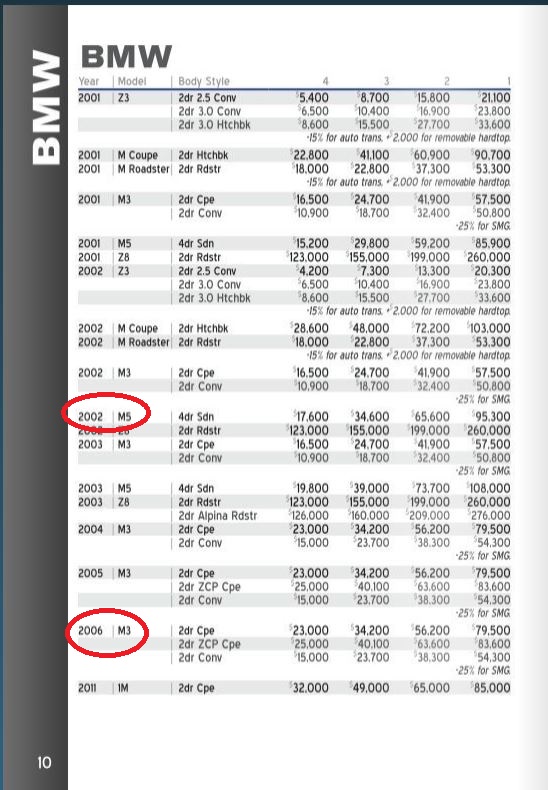

Hagery is out with their latest pricing guide. While I think Hagerty anticipates the market a bit and has a vested interest the trend is clear. I’d judge the condition of both my cars as halfway between 3 and 2 on their scale:

Get one while you can. If you’re willing to tackle some DIY maintenance the ownership experience IMO will be more enjoyable and you’ll also save a good bit of money.

UPDATE 8/16:

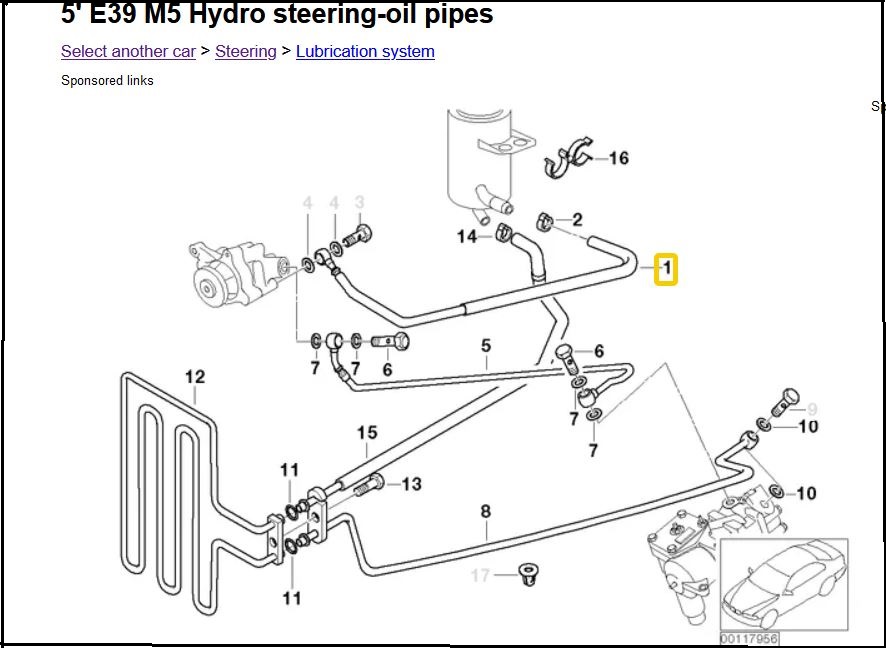

During the Craftsmans DIY event I noticed that one of my power steering hoses had a slow leak. On 8/7 Scandanavian Import Service Center in Rockville, MD hosted the NCC chapter for another DIY event and I tackled the replacement.

Initially I was going to replace just the weeping hose, but then decided why not do both hoses and the power steering reservoir. As far as I know the reservoir had never been replaced. The diagram from RealOEM was a little confusing because I couldn’t clearly understand which was the lower hose going to the pump (the one weeping, #1 in diagram) vs. the one that went into the oil cooler (#15).

I was greatly assisted by this video featuring the E39 expert Ryan Schultz of E39Source. Mechanics Victor and Carlos were friendly and helpful when I needed a second pair of hands or expert advice. Scandanavian Import Service Center is too far away for me being in Alexandria but I would highly recommend anyone in the Rockville area to seek them out next time your vehicle needs service.

Lower hose disconnected from power steering pump

Hose to the cooler – lower one in picture, RealOEM diagram is incorrect as it shows top hose

New hoses snaked back up and ready to attach to new reservoir

I also drained the radiator and refreshed the coolant, and replaced a couple of bolts on the underbody panel. It was a satisfying DIY that could warrant its own post but I had just written about the M5 so this update will do.

Hello Mr,

does kevin anderson still sells heat shields for BS module for a BMW E39 six-in-line.

If so, what’s the price and how to obtain one ?

Thanks.

Good evening,

Is he still selling that abs heat shield I’d not would you be able to provide the dimension. I am really interested in obtaining by buying it or making one close to it.

Thank you for your reply

Nice write up Chris! I replaced my power steering lines as well, and I agree the realoem website is confusing. If I remember correctly, power steering lines for #15 and #8 are swapped and this cause a small leak (very frustrating) because there was tension in the lines. After swapping the lines, no leak!